Class 58 Models | O Guage

Class 58 models in ‘O gauge’

You wouldn’t believe it, but it’s true! Not content with having a Class 58 available in N and OO gauges, there is a company producing a Class 58 model in the 1:43 ‘O’ gauge, basically completing the set!

The locomotive is from the extensive range of very high quality kits from David J Parkins of Modern Motive Power. Simon Varnam and Dave Butterworth of Building O Gauge Online are undertaking the commissioned build of a Class 58 from this range of kits for a customer. Obviously the Class 58 Locomotive Group is helping out where possible.

Simon writes: “Building O Gauge Online started life in 2004 as a method of transferring very high resolution photographs of model locomotives between myself and a few friends. In the intervening years it has evolved to become what it is today, a showcase of locomotives and rolling stock in 1:43 scale (7mm to 1 foot) all or mostly post BR steam era, built to the highest possible standards with as much prototypical detail as possible.”

“Some of the locomotives and rolling stock shown in the online gallery belong to either Dave or myself while some are commissioned builds for other people. We show every step of construction for most of what we build, from taking it out of the box to the finished item. Every picture has a text associated with it and there are special sections dealing with customisation, extra detail and computer control (DCC).”

“A lot of what we build is produced by a company called Modern Motive Power who have supported us over the years and believed 100% in what we are trying to achieve. A lot of research and photography of the real thing has gone into this build to try and make it as accurate as possible”.

So, to the models. Below is some background information on the models which has been provided to the C58LG, along with the photographs to illustrate the construction stages. We will bring updates and more photos as the model takes shape into the finished product.

Of particular interest to visitors of this website will be the Class 58 (58049) which is a commissioned build. The finished locomotive will be in Coal Sector livery, fully computer controlled and with onboard engine sound. The sound is not currently from a 58 but it is from the correct engine type. As soon as a working Class 58 is available to record some sample sounds from, the computer section will be reprogrammed to properly reflect the true sound of the class. The scale model will also feature realistic diesel exhaust and full lighting.

The kits are all constructed from brass, nickel silver, whitemetal (similar to pewter), lost wax brass castings in the case of the complex pipe work on a Class 58 buffer beam and the occasional resin casting.

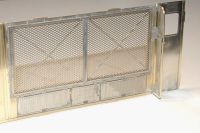

Apart from the castings everything starts out flat on etched metal frets. The parts have etched detail on them and once they are released from the fret they are then mostly folded to form a shape. In some instances many of these folded items are added together to form much more complex structures. Some items are not folded but are laminated together to form raised detail, the body side doors on the Class 58 being an example of this. The main body side is one large brass etching onto which the doors, made from nickel silver, are added. Each door is constructed from two nickel silver parts laminated together, so for the Class 58 which has 32 body side doors there are 64 nickel silver etches. Another example of the laminating technique is the solebar on the Class 58. To achieve scale thickness several brass parts are laminated together and the edge made smooth.

Apart from the castings everything starts out flat on etched metal frets. The parts have etched detail on them and once they are released from the fret they are then mostly folded to form a shape. In some instances many of these folded items are added together to form much more complex structures. Some items are not folded but are laminated together to form raised detail, the body side doors on the Class 58 being an example of this. The main body side is one large brass etching onto which the doors, made from nickel silver, are added. Each door is constructed from two nickel silver parts laminated together, so for the Class 58 which has 32 body side doors there are 64 nickel silver etches. Another example of the laminating technique is the solebar on the Class 58. To achieve scale thickness several brass parts are laminated together and the edge made smooth.

Some small complex shapes like multiple working sockets, horns, small pipe fittings and air tanks are cast from whitemetal and added to the brass items during construction.

Everything is soldered together. Seldom do we use glue of any kind. Items are fluxed using liquid flux and then soldered using a range of solders that melt at different temperatures depending on what the items being joined together are made from. Almost all of the solders we use melt at much lower temperatures than standard electrical solder.

Where possible we glass glaze the locomotives, partially for effect and partially because the glazing very often has to be in place pre painting. Glass is totally resistant to the solvent based paints we use to prime the metal before adding top coat colours.

Where possible we glass glaze the locomotives, partially for effect and partially because the glazing very often has to be in place pre painting. Glass is totally resistant to the solvent based paints we use to prime the metal before adding top coat colours.

We add many extra features to the kits during the construction phase. Diesel exhaust is provided by a small smoke generator which heats up a very thin smoke oil and vaporises it. This is then expelled through the exhaust ports via pipe work and is fan assisted to give that nice plume so often seen rising from the real thing.

Roof fans are driven by small electric motors. The wheels are driven by electric motors (one per bogie) which act on two of the three axles via worm gears. Power is supplied to the locomotive from the track as is traditional in model railways. An enhancement to this arrangement is DCC (Digital Command Control) where instead of there being a variable voltage on the track, there is 100% full voltage available 100% of the time. Riding on this voltage is a computer signal which a locomotive will respond to if that signal is meant for that particular locomotive. Processing of the information is performed by a small onboard microcomputer called a decoder. This in turn controls all the motors, lights, special effects and also produces sound in many cases. The advantages of this method of control are many. We can have lights on when the locomotive is stationary, we can have more than one locomotive on the same track moving at a different speed or even in the opposite direction and control over speed is much more realistic. When you tell them to stop, they do, but not immediately. Speed decreases gradually in a gentle curve as it would in real life. Sounds generated by the onboard computer are tied into the speed of the locomotive, so when you apply power from a standing start you get that increase in revs and turbo whistle. In a similar way, when the locomotive

Roof fans are driven by small electric motors. The wheels are driven by electric motors (one per bogie) which act on two of the three axles via worm gears. Power is supplied to the locomotive from the track as is traditional in model railways. An enhancement to this arrangement is DCC (Digital Command Control) where instead of there being a variable voltage on the track, there is 100% full voltage available 100% of the time. Riding on this voltage is a computer signal which a locomotive will respond to if that signal is meant for that particular locomotive. Processing of the information is performed by a small onboard microcomputer called a decoder. This in turn controls all the motors, lights, special effects and also produces sound in many cases. The advantages of this method of control are many. We can have lights on when the locomotive is stationary, we can have more than one locomotive on the same track moving at a different speed or even in the opposite direction and control over speed is much more realistic. When you tell them to stop, they do, but not immediately. Speed decreases gradually in a gentle curve as it would in real life. Sounds generated by the onboard computer are tied into the speed of the locomotive, so when you apply power from a standing start you get that increase in revs and turbo whistle. In a similar way, when the locomotive  is told to stop it assumes this to be a brake application and you will hear brake squeal. If you then apply power again you will hear the brakes lift off. Locomotives can be made to work in multiple as per the real thing and will all respond to commands sent to the lead locomotive. We use this feature as a crowd stopper at exhibitions because when you have three locomotives all coupled together in multiple working you actually hear three sets of brakes come off when the locomotives are told to move, there is a tiny delay between each one. Sounds great!

is told to stop it assumes this to be a brake application and you will hear brake squeal. If you then apply power again you will hear the brakes lift off. Locomotives can be made to work in multiple as per the real thing and will all respond to commands sent to the lead locomotive. We use this feature as a crowd stopper at exhibitions because when you have three locomotives all coupled together in multiple working you actually hear three sets of brakes come off when the locomotives are told to move, there is a tiny delay between each one. Sounds great!

The onboard computers are supplied by a British company, South West Digital. All sounds are recorded from real full size locomotives of the correct Class and are held in the computer’s onboard memory. At present we do not have a Class 58 recording but as soon as the opportunity presents itself to sample sound from a working locomotive this will become part of the range.

I hope many of you have found this article interesting. Dave and myself spend quite a lot of time researching many of the projects we construct which often brings us into contact with organisations like The Class 58 Locomotive Group and other groups primarily involved with the full size version. You do get some strange looks when you request to lie in the four foot under a locomotive to photograph the rear of a buffer beam and at open days where there are crowds of people trying to take nice three quarter shots of locomotives. You can usually guarantee one of us will be in the way photographing something of interest from a distance of no more than a couple of feet. On the whole though, groups like the C58LG and many of the preserved lines are only too pleased to accommodate our request as long as we demonstrate a level of health and safety awareness and are prepared to dress up in bright orange clothing. Without groups like this one our task would be much more difficult.

I hope many of you have found this article interesting. Dave and myself spend quite a lot of time researching many of the projects we construct which often brings us into contact with organisations like The Class 58 Locomotive Group and other groups primarily involved with the full size version. You do get some strange looks when you request to lie in the four foot under a locomotive to photograph the rear of a buffer beam and at open days where there are crowds of people trying to take nice three quarter shots of locomotives. You can usually guarantee one of us will be in the way photographing something of interest from a distance of no more than a couple of feet. On the whole though, groups like the C58LG and many of the preserved lines are only too pleased to accommodate our request as long as we demonstrate a level of health and safety awareness and are prepared to dress up in bright orange clothing. Without groups like this one our task would be much more difficult.

Simon Varnam & Dave Butterworth

Building O Gauge Online

www.7mmlocomotives.co.uk

References

Modern Motive Power - http://www.djparkins.clara.net/mmp/mmpmast.htm

South West Digital - http://www.southwestdigital.co.uk/